Prevent up to 30% of annual energetic financial losses.

Predictive maintenance

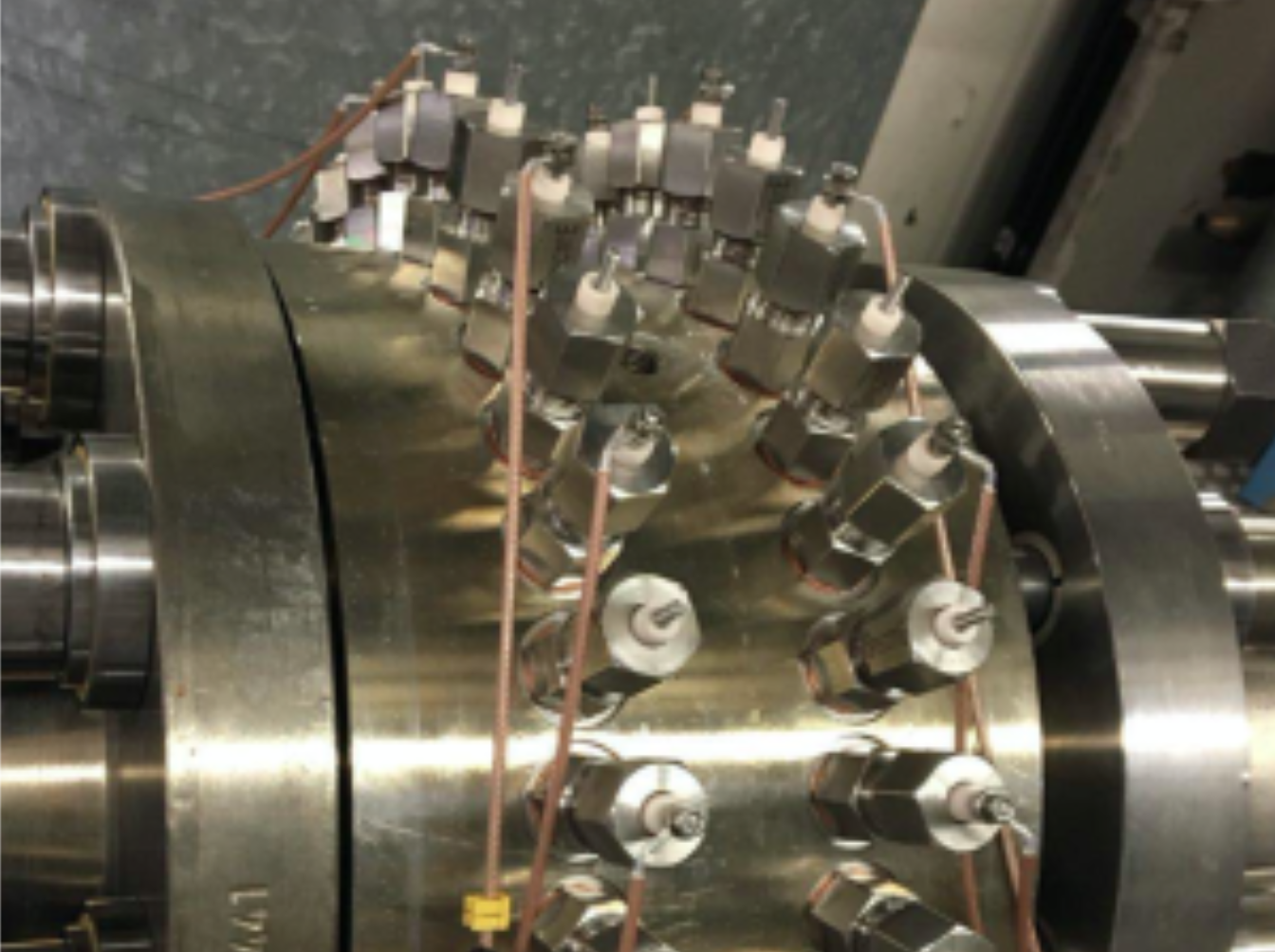

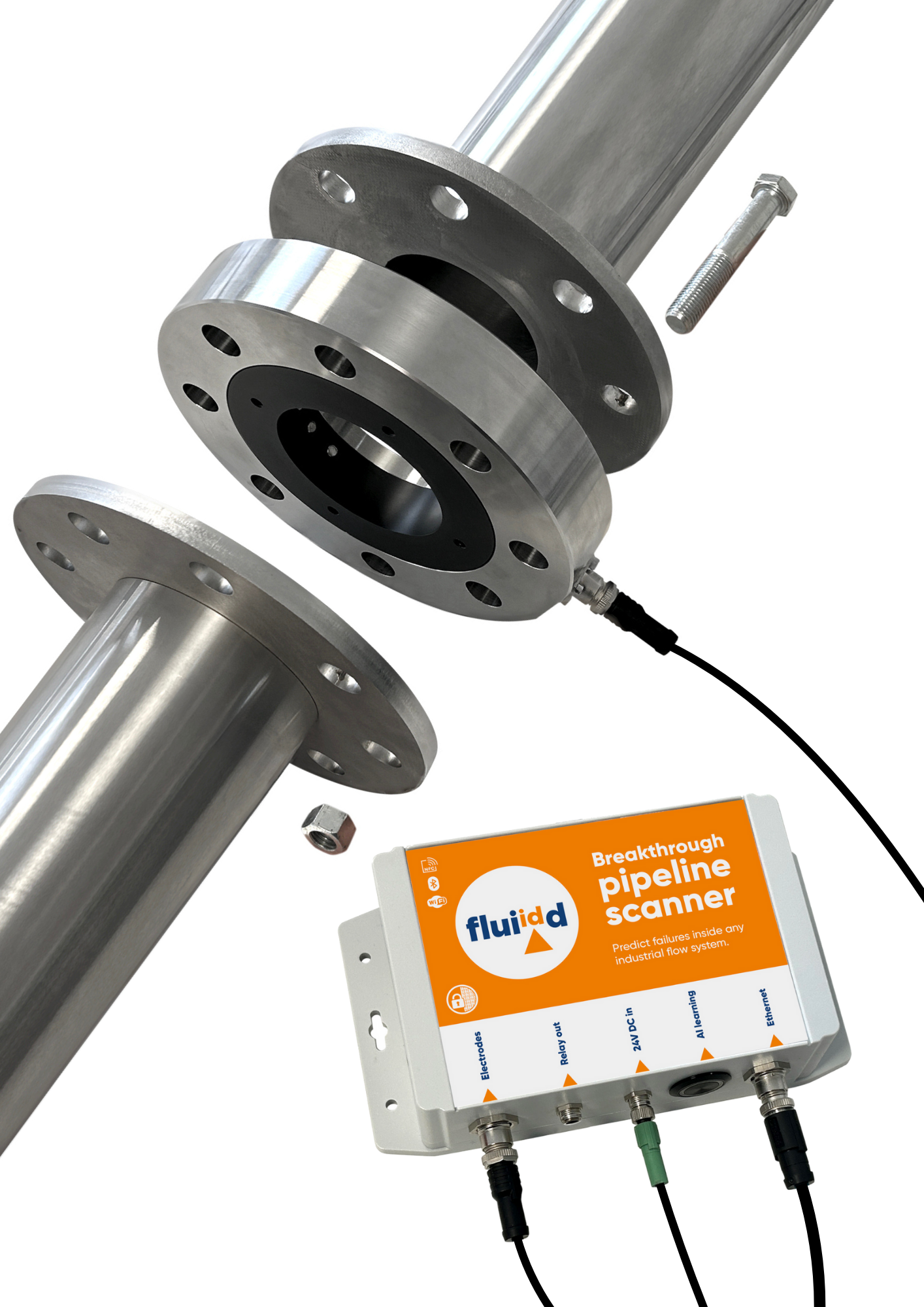

SCAN42, the new generation of industrial imaging

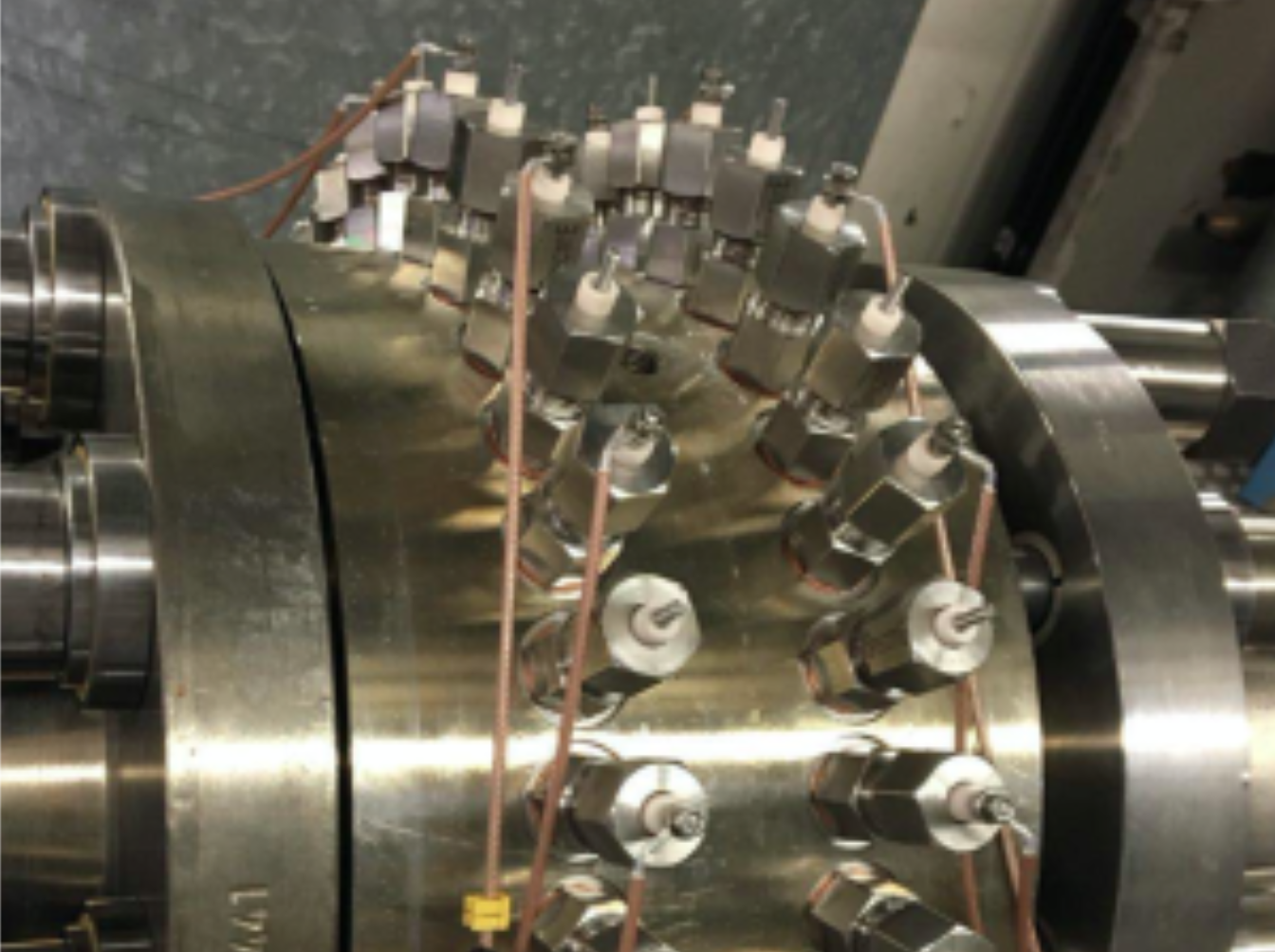

SCAN42 is an innovative imaging system designed for analyzing multiphase flows. It measures the flow rates of each phase (liquid, gas, solid) in real time with 97.4% accuracy. Thanks to its ultra-fast imaging, it provides clear and continuous visualization of complex flows, even in dynamic environments, enabling industrial processes to be optimized with unprecedented traceability.

The integration of artificial intelligence into SCAN42 revolutionizes anomaly detection: it identifies critical defects such as cavitation, air bubbles, or foreign bodies without contact and without disrupting the flow. This non-invasive approach ensures proactive monitoring and immediate diagnosis, which are essential for preventing breakdowns and performance losses in the most sensitive installations.

With its ability to capture 31,250 images per second, SCAN42 analyzes extremely fast phenomena (up to 300 m/s) even under extreme conditions (600 °C, 250 bar). Its robustness and versatility allow it to adapt to the most severe industrial constraints, from high-pressure pipelines to thermal reactors. It thus transforms raw data into actionable information, ensuring total control of your flows.

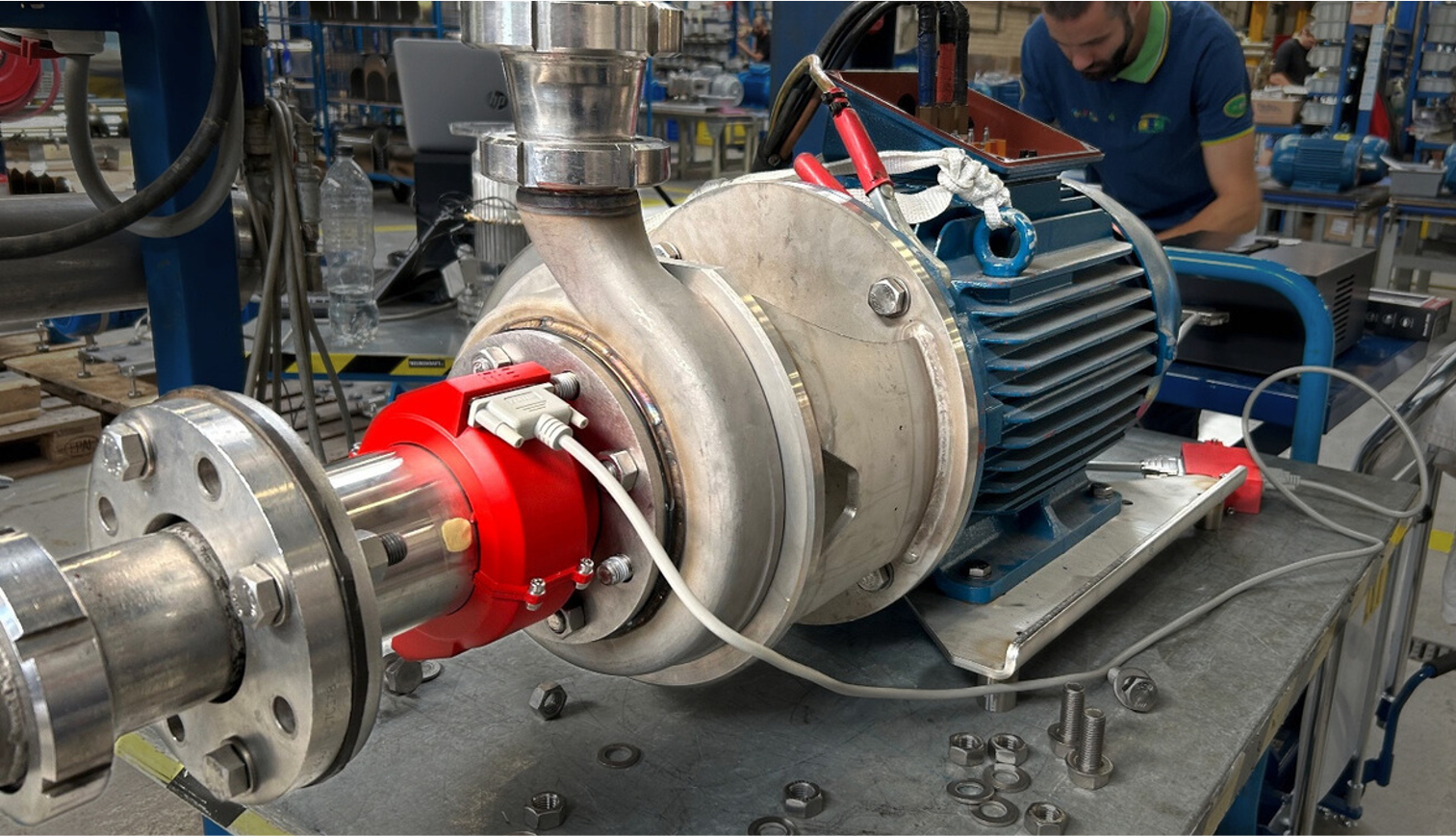

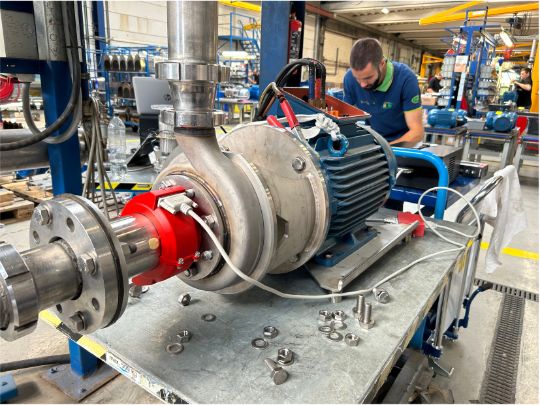

Pump, pipe or valve: where to place the SCAN42 for optimal performance

In suction (cavitation detection, dry running) or outlet (solids, transient anomalies).

On a straight section, ideally after critical equipment (exchanger, filter, dosing unit) for continuous monitoring.

Immediately upstream of the valve to monitor fouling/clogging and ensure operation.

ENRICH YOUR VISION

Download our latest

sales brochure.

Nuclear industry, water, agri-food, semiconductors, etc.

FAQ about SCAN42

© 2024 All rights reserved.